Food Freeze Dryer

We offer you a complete food drying solution with long-term technical support and fast response. Customization is available. Superior quality and Best price!

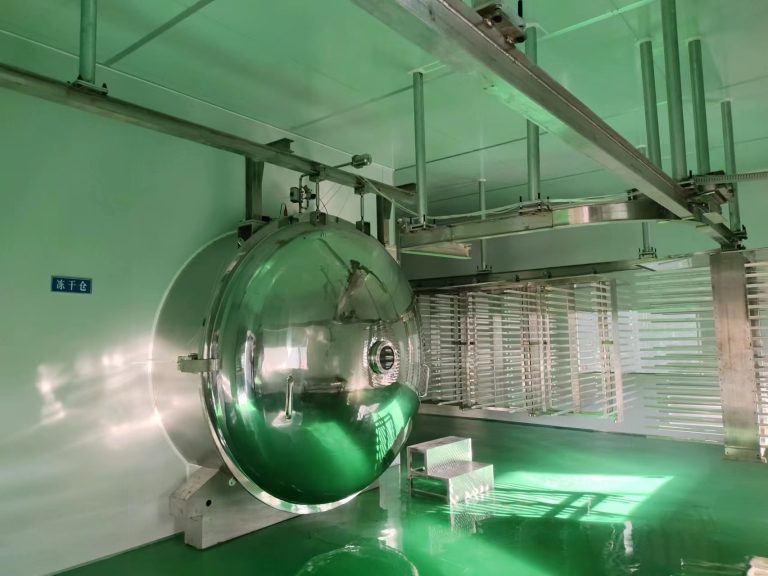

Food Freeze Dryer

Food freeze dryer is also called food vacuum freeze dryer, food freeze dryer, food freeze drying equipment. It can be used for vacuum freeze-drying processing of meat, vegetables, fruits, aquatic products, milk, beverages, soups, health care products, Chinese medicinal materials and other types of food, and freeze-dried food meets the requirements of natural, nutritious and convenient.

Product Overview

The FZG series freeze dryer is produced using standardized manufacturing processes, catering to the processing and production needs of various foods, traditional Chinese herbs, and industrial raw materials. It utilizes high-quality materials and incorporates imported components widely accepted in the industry. Additionally, it employs advanced manufacturing techniques, ensuring that the equipment fully complies with GMP standards.

ALL AREA FOR DIFFERENT FOOD FREEZE DRYER

| TF-FZG-15 | |

| Freeze-drying area(m²) | 15.74 |

| Processing capacity(Kg) | 150 |

| Temperature range of the shelves | -45℃ to +80℃ |

| Condenser Final Temperature(℃) | -60℃ |

| Ice catching capacity(Kg) | 300 |

| Dimension of product(L × W × H)(mm) | Chamber:6700×1800×3500 (Final dimension based on design) |

| Weight | 7000kg |

| Power(kW) | 71 |

| TF-FZG-20 | |

| Freeze-drying area(m²) | 21 |

| Processing capacity(Kg) | 200 |

| Temperature range of the shelves | -45℃ to +80℃ |

| Condenser Final Temperature(℃) | -60℃ |

| Ice catching capacity(Kg) | 400 |

| Dimension of product(L × W × H)(mm) | Chamber:7000×2100×3600 (Final dimension based on design) |

| Weight | 7500kg |

| Power(kW) | 86 |

| TF-FZG-30 | |

| Freeze-drying area(m²) | 32.46 |

| Processing capacity(Kg) | 300 |

| Temperature range of the shelves | -45℃ to +80℃ |

| Condenser Final Temperature(℃) | -60℃ |

| Ice catching capacity(Kg) | 550 |

| Dimension of product(L × W × H)(mm) | Chamber:8050×2500×3600 (Final dimension based on design) |

| Weight | 10000kg |

| Power(kW) | 120 |

| TF-FZG-50 | TF-FZG-50-Ra | |

| Freeze-drying area(m²) | 50.22 | 51.48 |

| Processing capacity(Kg) | 500 | 500 |

| Temperature range of the shelves | -45℃ to +80℃ | Room Temperature to +120℃ |

| Coldtrap Temperature(℃) | -60℃ | ≤-65℃ |

| Ice catching capacity(Kg) | 750 | 500 |

| Dimension of product(L × W × H)(mm) | 9400×2500×3600 (Final dimension based on design) |

/ |

| Dimension of freeze storage(L × W × H)(mm) | / | 4040×3040×4200 (Final dimension based on design) |

| Weight | 14000kg | / |

| Installed Power of freeze dryer(kW) | / | 135 |

| Installed Power of freeze storage(kW) | / | / |

| Power(kW) | 160 | / |

| TF-FZG-100 | TF-FZG-100-Ra | |

| Freeze-drying area(m²) | 98.68 | 112.2 |

| Processing capacity(Kg) | 1000 | 500 |

| Temperature range of the shelves | -45℃ to +80℃ | Room Temperature to +120℃ |

| Coldtrap Temperature(℃) | -60℃ | ≤-65℃ |

| Ice catching capacity(Kg) | 1500 | 1000 |

| Dimension of product(L × W × H)(mm) | 16000×2500×3600 (Final dimension based on design) |

/ |

| Dimension of freeze storage(L × W × H)(mm) | / | 5500×3500×4420 (Final dimension based on design) |

| Weight | 20000kg | / |

| Installed Power of freeze dryer(kW) | / | 188 |

| Installed Power of freeze storage(kW) | / | 55 |

| Power(kW) | 250 | / |

| TF-FZG-125 | |

| Freeze-drying area(m²) | 129.4 |

| Temperature range of the shelves | -45~50℃ to +80℃ |

| Dimension of shelves(L × W × H)(mm) | 7990×541×18 |

| Number of shelves | (15+1)×2,(upper radiant shelf) |

| Final Temperature(℃) | -65℃ ~ -70℃ |

| Ice catching capacity(Kg) | 2000kg |

| Power(kW) | 320 |

| Dimension of product(L × W × H)(mm) | Chamber:15000×2500×2900 Module:5000×2500×3600 (Final dimension based on design) |

| Weight | 20000kg |

| TF-FZG-150 | TF-FZG-150-Ra | |

| Freeze-drying area(m²) | 148 | 157.08 |

| Processing capacity(Kg) | 1500 | 1500 |

| Temperature range of the shelves | -45℃ to +80℃ | Room Temperature to +120℃ |

| Coldtrap Temperature(℃) | -60℃ | ≤-65℃ |

| Ice catching capacity(Kg) | 2250 | 1500 |

| Dimension of product(L × W × H)(mm) | 22000×2500×3600 (Final dimension based on design) |

/ |

| Dimension of freeze storage(L × W × H)(mm) | / | 8000×3500×4420 (Final dimension based on design) |

| Weight | 30000kg | / |

| Installed Power of freeze dryer(kW) | / | 206 |

| Installed Power of freeze storage(kW) | / | 84 |

| Power(kW) | 280 | / |

| TF-FZG-200 | TF-FZG-200-Ra | |

| Freeze-drying area(m²) | 197.4 | 201.96 |

| Processing capacity(Kg) | 2000 | 2000 |

| Temperature range of the shelves | -45℃ to +80℃ | Room Temperature to +120℃ |

| Coldtrap Temperature(℃) | -60℃ | ≤-65℃ |

| Ice catching capacity(Kg) | 3000 | 2000 |

| Dimension of product(L × W × H)(mm) | 29000×2500×3600 (Final dimension based on design) |

/ |

| Dimension of freeze storage(L × W × H)(mm) | / | 10800×3500×4420 (Final dimension based on design) |

| Weight | 36000kg | / |

| Installed Power of freeze dryer(kW) | / | 329 |

| Installed Power of freeze storage(kW) | / | 103 |

| Power(kW) | 520 | / |

Equipment features:

1. The freeze-drying chamber and partition strictly adhere to GMP requirements. The cylinder body is made of 304 stainless steel with a mirror-polished interior, surpassing the manufacturing processes and standards of conventional food freeze dryer manufacturers in China.

2. It features an integrated design of the freeze-drying chamber and cold trap, with a front chamber and rear trap layout. An observation window with illumination is provided to facilitate viewing inside the chamber. The design ensures easy cleaning and eliminates sanitary dead corners.

3. The partitions are custom-made based on customer needs, and the 304 stainless steel partitions are processed with surface-drawn square steel profiles, providing a smooth surface that is easy to clean and maintain good hygiene.

4. The water-catching coil in the cold trap is made of clean stainless steel. Customers can choose between integral and separate structures based on their requirements.

5. The refrigeration system components are equipped with high-standard imported brands, offering strong cooling capacity, fast cooling speed, and stable and reliable performance.

6. The vacuum system provides a variety of vacuum pump combinations to meet customer demands, using high-quality vacuum pumps from AiFa Technology.

7. It employs an imported Omron PLC control system for easy data storage and operation. The control system offers both automatic and manual modes, with the flexibility to switch between them. Multiple sets of process settings can be configured, and formula modifications are possible during the drying process, allowing for arbitrary steps.

8. It employs immersion or steam defrosting, providing fast and thorough defrosting and cleaning.

9. It includes a pre-freezing function, eliminating the need for an external pre-freezing storage, and mitigating material liquefaction and contamination risks.

10. It comes with process adjustment capabilities, featuring curve-controlled temperature and temperature and vacuum control adjustment functions to meet different material processing requirements.

11. The partition’s intermediate oil conducts heat without the need for steam, ensuring environmental friendliness and safety compliance.