Biopharmaceutical Freeze Dryer

We offer you a complete food drying solution with long-term technical support and fast response. Customization is available. Superior quality and Best price!

Biopharmaceutical Freeze Dryer

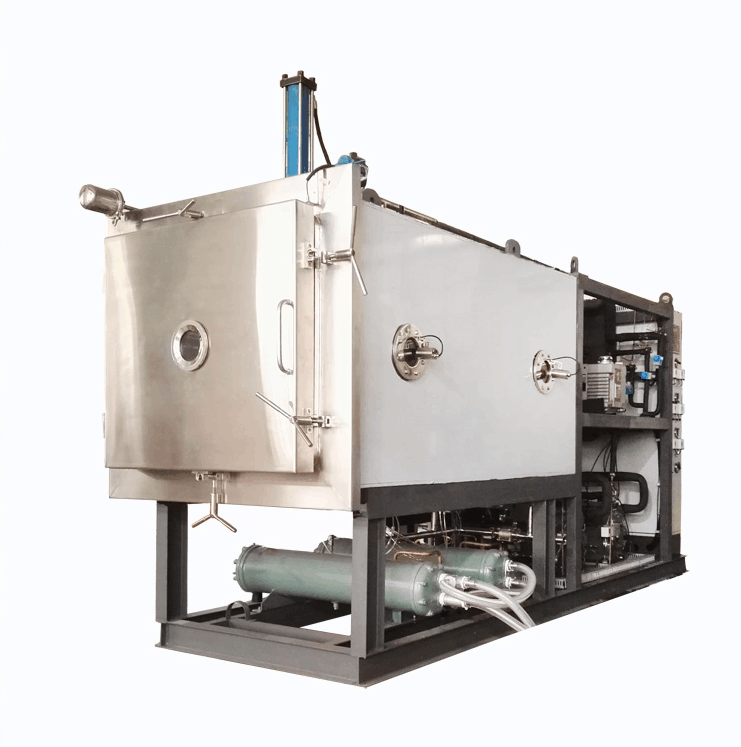

Bioproduct freeze dryer is a specialized machine used in biopharmaceuticals to preserve and store biological products like proteins and vaccines. It achieves this by freezing the biological substance at low temperatures, followed by removing moisture in a vacuum environment, resulting in a stable, long-term dry product. This equipment plays a crucial role in the biopharmaceutical industry, ensuring the preservation of product integrity and activity for medical and research purposes.

Product Overview

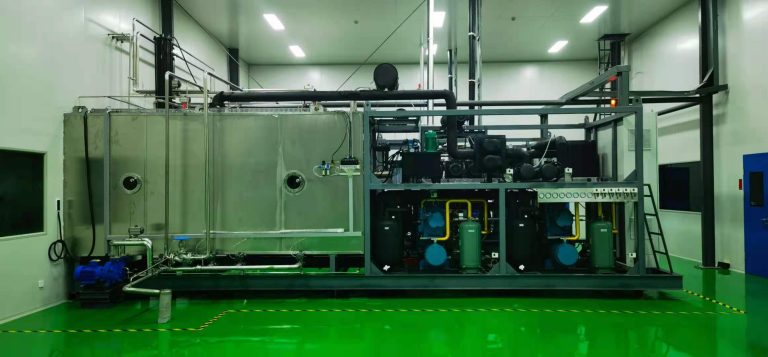

The LYO Biopharmaceutical Freeze Dryer is produced using standardized manufacturing processes, reducing manufacturing costs and shortening production cycles while ensuring performance and reliability. The design of the freeze dryer prioritizes safety, versatility, reliability, and long service life while also ensuring the safety of users and the environment. The design is based on mature technology and employs high-quality materials and components widely accepted in the biopharmaceutical industry. Additionally, it utilizes advanced manufacturing techniques, ensuring that the equipment fully complies with cGMP standards.

ALL AREA FOR BIOPRODUCT FREEZE DRYER

| TF-LYO-0.5 | |

| Condensation Final Temperature(℃) | ≤-80℃ |

| Shelves Temperature range | -55℃ to +70℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 5 |

| Freeze-drying area (m²) | 0.54 |

| Water-catching capacity (Kg) | 10 |

| Power(kW) | 7 |

| TF-LYO-1 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 10 |

| Freeze-drying area (m²) | 1.08 |

| Water-catching capacity (Kg) | 20 |

| Power(kW) | 11 |

| TF-LYO-2 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 20 |

| Freeze-drying area (m²) | 2.16 |

| Water-catching capacity (Kg) | 40 |

| Power(kW) | 15 |

| TF-LYO-3 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 30 |

| Freeze-drying area (m²) | 3.24 |

| Water-catching capacity (Kg) | 60 |

| Power(kW) | 20 |

| TF-LYO-5 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 50 |

| Freeze-drying area (m²) | 5.4 |

| Water-catching capacity (Kg) | 100 |

| Power(kW) | 36 |

| TF-LYO-10 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 100 |

| Freeze-drying area (m²) | 10.8 |

| Water-catching capacity (Kg) | 200 |

| Power(kW) | 60 |

| TF-LYO-15 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 150 |

| Freeze-drying area (m²) | 10.8 |

| Water-catching capacity (Kg) | 300 |

| Power(kW) | 75.7 |

| TF-LYO-20 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 200 |

| Freeze-drying area (m²) | 20.18 |

| Water-catching capacity (Kg) | 400 |

| Power(kW) | 90 |

| TF-LYO-40 | |

| Condensation Final Temperature(℃) | ≤-75℃ |

| Shelves Temperature range | -55℃ to +80℃ |

| Vacuum degree (Pa) | ≤1 |

| Processing capacity (Kg) | 400 |

| Freeze-drying area (m²) | 41.86 |

| Water-catching capacity (Kg) | 800 |

| Power(kW) | 211 |

Equipment features

- The cabinet material is AISI 304 or AISI 316L, and the interior of the cabinet is designed with rounded corners to facilitate access and minimize dead corners.

- All internal welds of the cabinet are treated and smoothed with surrounding materials. During partition manufacturing, materials are uniformly heated to avoid stress between independent welds, ensuring the smoothness of the shelves.

- Low-viscosity silicone oil is used as the heat transfer medium, ensuring good temperature uniformity at extremely low temperatures on the shelves.

- Main unit components are sourced from imported brands to ensure equipment quality.

- Production follows ISO9001 quality management system, and the manufacturing process ensures full compliance with cGMP standards.

- The PLC computer system controls all functions of the freeze dryer. Based on the process parameters and programs stored in memory, the PLC can complete the operation of the entire production system. The system is stable and secure.

- 4Q certification documents can be provided, along with comprehensive training and services.